Wednesday 25 January 2023

Reading felt like weaving

Recently I've been doing a bit of ghost writing, as a way of bringing in some funds for childcare, and I was pleasently surprised by how much I enjoyed it. The piece I was writing was one tenth the size of the PhD, had a close deadline and was about an area of weaving i've always found slightly mysterious and not at all in the same vein as my thesis. All of these elements came together and provided me with a positive writing experience - a feeling i've not had for years. Anyway, I was so touched with the client's feedback, that I had to shout about it.

Friday 16 December 2022

Here is a clip of me weaving in the virtual world, part of my research practice for the last three years. I have a headset on my face and a controller in each hand, behing me is a real life woven piece, made at a time when my body was growing a new life, when my thinking was shifting. I am using an Oculus 2 headset because it doesn’t require a high spec gaming computer on which to run. It is as portable as VR headsets get.

The more I use VR, the less I enjoy it. In fact, I think i’ve reached the point of me disliking it and I’m going to unpick why I think that is. The headset is uncomfortable and because of this I am always aware of its presence - this piece of heavy, ugly (and it is ugly - a big white plastic box) technology strapped to my face. It pushes my glasses into the bridge of my nose and sucks to my forehead and when I remove the mask, it has left a pink ring on my forehead as if to say - i’ve used you, you can’t forget me that easily.

The controllers are plastic. The entire Oculus 2 headset is plastic - slightly matt in texture, but still with that unmistakable plastic, unsatisfying feel that doesn’t sing to one’s sense of touch. The controllers are a big hindrance in the ease of use - the headset does have hand tracking technology, but this is very crude and clunky - there is no way it captures the small gestures needed when using Gravity Sketch. The controller buttons make that unmistakable sound of plastic being pushed into plastic by clammy fingers.

When in this virtual space, the light is jarring and left me squinting into the daylight when it was taken off. There certainly is no way it imitates natural light. It just feels like i’m staring at yet another screen and I begin to get a headache and start to feel dizzy after about fifteen to twenty minutes.

Wearing the VR headset is a novelty and the action of weaving in VR is certainly informative and intriguing, however the physicality of using the hardware is unpleasant, which in my opinion defeats the object of weaving. Weaving in its raw form is physical, it is sensorial in all aspects. The sensation of touching, smelling, listening to the fiber, the tools and the loom taps into the primeval human and uncovers this intuitive knowledge within the weaver.

Wednesday 20 May 2020

My 3 favourite tools

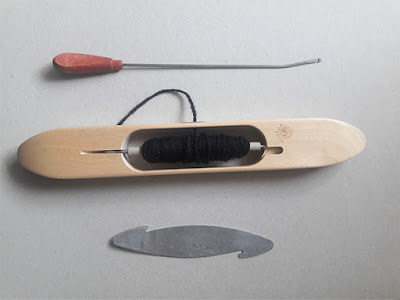

The top tool is a threading hook - the red bulbous end is

wooden and the long needle like end is metal with a tiny hook at the very tip.

The needle slides through the eye of the heddle to catch a warp end. I then

slide it back through the heddle and move onto the next warp end. I often tend

to hold the threading hook in my teeth as I quickly adjust heddle’s and warp –

there is something really satisfying about the metallic taste in my mouth

alongside the textured warp yarns in my fingers. The middle tool is called a

shuttle. It is wooden, with rollers along the bottom that enables the shuttle

to glide easily through the weave shed. This is a very tactile object which

makes a really rewarding clunky sound when it is pushed through the shed. The

shuttle holds the weft yarn that is interlaced at right angles with the warp

yarn to create the fabric. The shuttle is a tool that is in constant use during

the hand weaving process it is a very personal object that many weavers often

adapt and personalise to suit their weaving habits and needs. The bottom tool

is an aluminium ‘Fish’ or Reed Hook that has a hook at either end for ease of

use. It is a very light, narrow tool that is slotted through the read dents to

catch the warp and to pull it back through the dent. This Fish is slightly bent

at one end. I think this is down to me being right-handed and threading the

loom from left to right – I must often put pressure on the end of this hook

when pulling it back through the dent this has led to the develop of the slight

curve. Another example of how weaving tools mould to the weaver.

Thursday 9 August 2018

Weaving in VR with Gravity Sketch

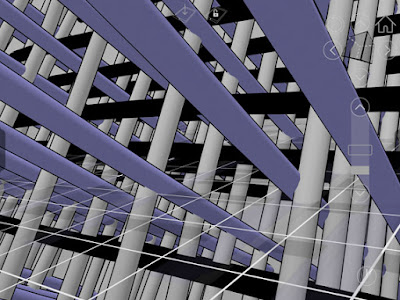

Gravity Sketch is a 3D modeling tool in VR. I am transported into a large, empty warehouse space where I have the room to create 3D structures. I lost all sense of time and awareness to my real surroundings.

This is a truly immersive tool that allows a more intuitive way of modeling in 3D, compared to Rhino. There was much more of a connection with the design process, as I had to use my whole body to create the structure - sweeping my arm from one corner of the room to the other, ducking under the lines i created and side-stepping others. Using the whole body to create the model in such an intangible space is very surreal. There is a direct involvement with the digital and it bridges the gap between the digital and the physical.

After a while though, I did start to feel quite disorientated and claustrophobic. On taking off the headset and coming back to the real world, I felt nauseous for a good few hours afterwards. I wonder if this motion sickness sensation was down to the constant changing of my surroundings in the virtual world? - Changing the scale of the structure, spinning them around, pushing them away.

Friday 23 February 2018

Tactile thought

I spent my morning winding a large skein of deep brown, soft and chunky Welsh wool into balls. Quiet time standing over a skein of yarn, stretched between two chairs, navigating my arm in a circular motion, guiding the wool. Inhaling the comforting lanolin scent.Feeling the warmth of the fibres as the yarn slipped through my fingers was meditative, giving me time to reflect on the tactility of my action and encouraging words to appear and sentences to form in my head. A practice in materiality and thinking and an antidote to the digital day to come.

Sunday 17 December 2017

Imposter

Dyslexia is an issue for me now more than it ever has been. It was picked up at the start of my MA, before that i'd just thought I was slower at, well, everything. Having found school a real challenge, despite my love for English literature, I struggled and felt I was simply inadequate compared to my classmates. I always found it easier to communicate using my hands and to express myself through making. I remember that confusing mix of emotions as a child and finding the only way to work it out was to take myself off to a quiet part of the house to glue things, sew things, paint things. My decision to study textiles as a BA was, I think, down to that feeling of comfort and understanding of the tactile. Materiality. This physical connection to the subject I was learning about propelled me forward academically and I begun to feel at ease with writing and to enjoy verbalising ideas and opinions.

The thing is... the overwhelming sense of adolecent inadequacy has once again reared its ugly head as I venture into the world of academia and PhD life. In the last three months, as I get to grips with the concept of doing a practice-led PhD, I've been bombarded with a series of 5 deadlines all within two weeks of each other. What's the problem? There are a few. I've been focusing so much on these written deadlines, that i've not done any practical work. There has been no tactility alongside my literary, and this leaves me feeling unrelaxed and uptight. Then there's the matter of thinking about all of these deadlines, which proves very unproductive. It feels like i'm stuck and can't move forward, past the worry of so many things to do. All work and no play has made Sophie an anxious person. I'm normally incredibly organised and can juggle many things under pressure. Because I know I can and i'm capable.

However, I don't know I can PhD it and I don't know I am capable. I've got the imposter syndrome and I don't know how to get rid of it. This uncertainty is making me feel even more inadequate, and so the downward spiral begins.

Breathe.

Thats out. Now to have a go at #1: Methodologies

Stream of consciousness as a tool?

Friday 17 November 2017

Happy Memories

Searching wildly through a mound of stuff, stored away in old wine crates, for some ink cartridges to satisfy my stationary craving, I came across these photos. Over five years ago a little project of mine, The Cow House, came to life for a summer of indigo dyeing, cakes, films and magic. These pictures almost epitomise my childhood memories of growing up on Dartmoor surrounded by stories. To have spent my formative years engulfed in my imagination fuelled by the moors, myths, ancient stone buildings, rivers and fruit trees was the stuff of fairytales. I see the farm worn concrete floor and ramshackle doors framed in a nostalgic summer light with Dad's hand made dolls house and see my past, but also my future.

A future of breathing life into forgotten things, non existent things. Maybe even bringing things into life - weavings, stories, children. Keeping a life of family and friendship in which to ground a future.

Monday 31 July 2017

Design for the Future: The Future is Weave

Weaving is archaic I hear you say. What place does a cottage craft have in this digital world? Combining the craft and the digital - the weave with the computer is something I am increasingly curious about. My love of weave stems from my fascination with structure, the tactile and construction, the black and the white, the ups and downs. The heavy mechanical sound, the steady reliable rhythm. Weave excites me.

The potential for a woven future is mostly untapped and asking to be explored. The perfect combination of weave structure and yarn can produce highly effective, functional materials with shock absorbency, bullet proofing, waterproofing, rigidity. What if I can magnify those properties by amplifying the structure and weaving off the loom, using 3D printing technology? My next three years will be dedicated to research of 3D woven materials for the circular economy.

Why am I interested in the circular economy? Why the hell not? Our children, our grandchildren and our planet need a future too and one way I can contribute to their future as a weave designer is to look at how I can reduce textile waste, use alternative materials, maybe even change the way companies and consumers view the product life cycle. Now, thats one hell of a challenge. I love challenges, especially ones I get to tackle with the help of others with expertise in different fields. The best innovation comes from collaboration with scientists, engineers, economists, architects... the list goes on. Innovation is the key to the future, It always has been.

The future for design must be circular.

The future for 3D printing is democratic.

The future for weaving is digital.

The future for us is working together.

The future for 3D weaving is emergency shelters, protective wear, sports wear, shoes, insulation, vehicle, interior, body, space, aerospace...

How exciting!

This blog post is a part of Design Blogger Competition organized by CGTrader

| Taken in 2013, Isle of Harris. Donald John Mackay at his Hattersley loom. |

The potential for a woven future is mostly untapped and asking to be explored. The perfect combination of weave structure and yarn can produce highly effective, functional materials with shock absorbency, bullet proofing, waterproofing, rigidity. What if I can magnify those properties by amplifying the structure and weaving off the loom, using 3D printing technology? My next three years will be dedicated to research of 3D woven materials for the circular economy.

|

| Image taken form Ellen MacArthur Foundation website |

Why am I interested in the circular economy? Why the hell not? Our children, our grandchildren and our planet need a future too and one way I can contribute to their future as a weave designer is to look at how I can reduce textile waste, use alternative materials, maybe even change the way companies and consumers view the product life cycle. Now, thats one hell of a challenge. I love challenges, especially ones I get to tackle with the help of others with expertise in different fields. The best innovation comes from collaboration with scientists, engineers, economists, architects... the list goes on. Innovation is the key to the future, It always has been.

|

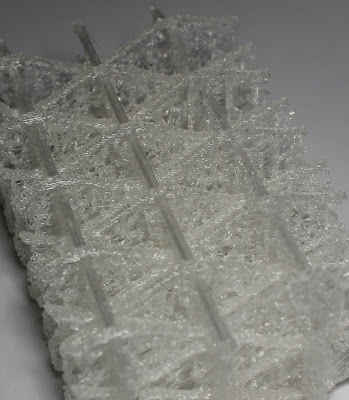

| A 3D print of a woven structure. |

The future for design must be circular.

The future for 3D printing is democratic.

The future for weaving is digital.

The future for us is working together.

The future for 3D weaving is emergency shelters, protective wear, sports wear, shoes, insulation, vehicle, interior, body, space, aerospace...

How exciting!

This blog post is a part of Design Blogger Competition organized by CGTrader

Tuesday 25 July 2017

Kiwis Flax. Plucked and Woven. My year without a loom.

A year off from the grinding reality of working your arse off for low pay just to be able to cover your London rent and a tiny desk in an over overcrowded studio only to find you're working your arse off and don't have time to use your desk to create what you do best... A year off from FOMO. The ever increasing social pressure of a better online presence, a better offline presence, marriage, babies, growing debt, mindfulness, health, fitness... BREATHE.

I met a boy. One year later we quit our jobs and found ourselves in New Zealand. The grass is always greener on the other side of the planet. Our intention was to explore, live life without stuff, bills, pressure and conform , meet family and make friends and maybe even to find our dream spot to put our roots down and to find my creativity again.

I found family, friends, open space to think and reflect, Kiwis, blisters, burns, backbreaking work, hot springs and new springs, Orcas and Albatros, the cold, the damp, the dark nights and the bird song, the earthquakes, resilience, determination and generosity.

We Wwoofed, worked, picked, cleared, waited, weeded, dug, killed, kayaked, bathed, dived, swam, trudged, tramped, stomped, slipped, fell, feared, moaned, shivered, smelled, went hungry, went thirsty, ate, feasted, licked, sucked, plucked, fished, drank, danced, clapped, sang, laughed, cried, comforted, argued, swore, kissed, touched, tickled, played, wove flax, sketched strangers, read mostly crap, dreamed of weaving, learned to live.

We didn't stay. I wanted to weave again.

Monday 9 November 2015

Gravity Sketch

I am in the process of testing a new software program,

Gravity Sketch, which has been developed to give designers a more intuitive

method of designing 3d forms. It is this transition between Gravity Sketch

software into Rhino and then into product I have been experimenting with. This process has

been a huge learning curve for me, as I find Rhino

totally unintuitive to navigate, which is where Gravity Sketch comes in.

On top of this designing process I've had to lean how to use various 3D

printer software and learn that patience has a whole other meaning

when dealing with all of them together on one computer, in a short space of time.

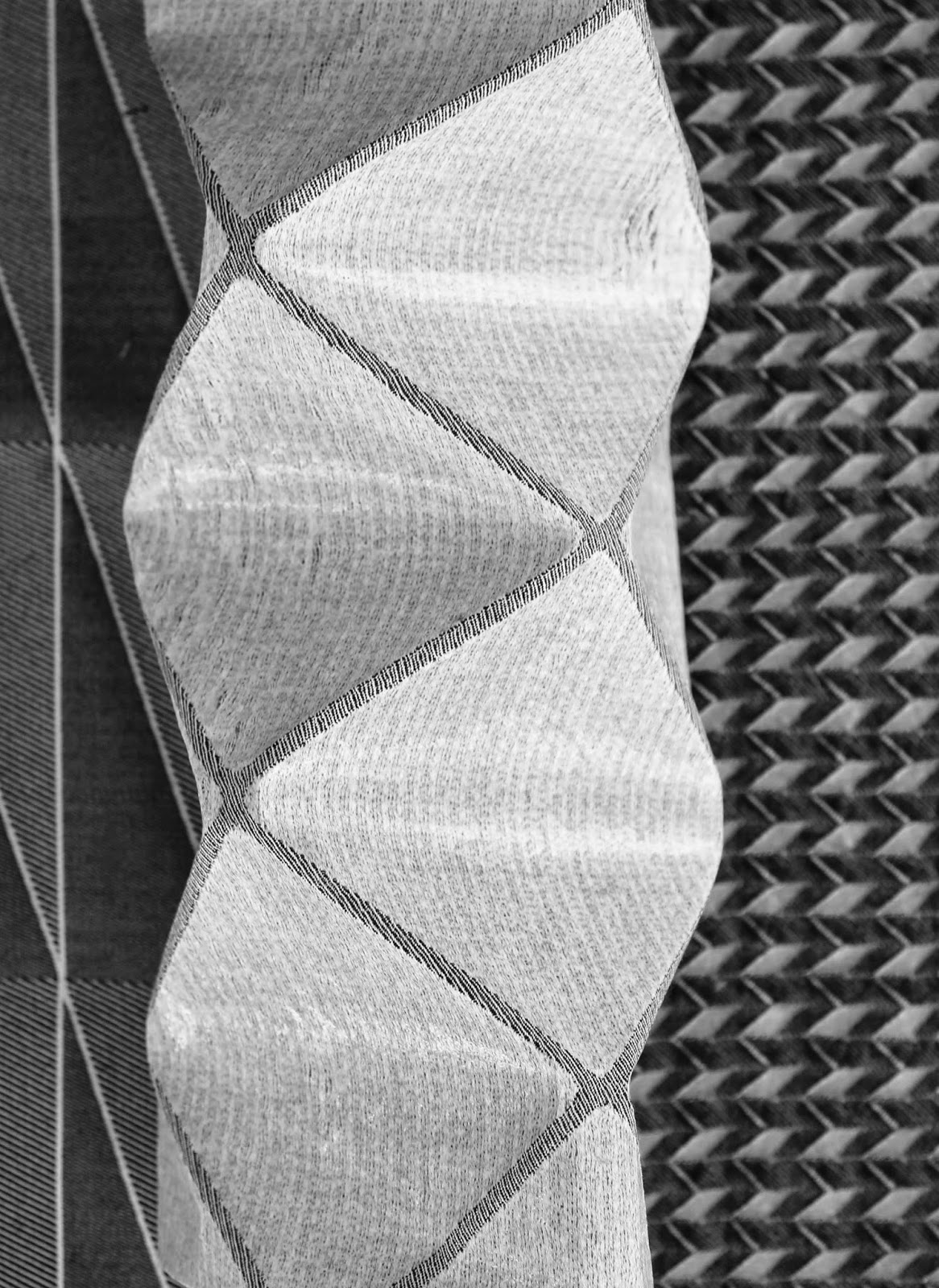

These Past Few Months - Weaving in 3D

My work is going in a really exciting direction at the

moment. Through an RSA - The Great Recovery project,

I have been using FabLab London as my base and source of all 3D printing

knowledge. Since July I've been developing 3D printed materials that are based

on woven structures, with the circular economy model ever present in

every stage of the design process.

Using the 3d printing facilities I am developing

material samples that aid my research into creating shock absorbing textiles

solely from one component. Cutting out any excess waste and additional

materials usually required for spacer/ shockproof fabric. Using a 3d printer to

create textiles enables me to transform traditional weave structures from the x

and y axis into the x,y and z. It frees one from the constraints of a loom and

adds a third dimension to the fabric.

Developing textiles for the circular economy is

achievable through the use of a 3d printer. A traditional weaving loom creates

waste at the start and finish of each warp and a selvedge along the edges of

the fabric that is then discarded. A 3d printer has none of this excess waste

textile.

Wednesday 18 February 2015

SITSELECT

Very happy to be a confirmed speaker in the SitSelect October conference, talking about advances in woven textiles.

Wednesday 14 January 2015

Sunday 11 January 2015

A Mill for a Tweed

Ambrose Vevers is a wood worker and a bee keeper, practicing on the wilds of Dartmoor. I needed a new warping mill and he wanted a waistcoat. What happened next was a skill swap between two craftsmen that culminated in the creation of a beautifully made warping mill (ash and elm) and a honeycomb hued tweed waistcoat made from Irish wool.

Tuesday 6 January 2015

6 Months Ongoing

Happy New Year. To kick off 2015 I am part of an exhibition with 9 other recent Royal College of Art graduates. Come along to see some exciting new projects.

Friday 12 September 2014

Thursday 4 September 2014

My Material at MoOD

My articulating material will be on show at this year's Innovation Platform in MoOD, Brussels. September 9th - 11th.

Tuesday 24 June 2014

Dezeen . IDE . RCA . Textiles

A fellow RCA IDE graduate, Oluwaseyi Sosanya invents a 3D weaving machine, in collaboration with me! Dezeen investigate.

Monday 23 June 2014

Sunday 15 June 2014

Thursday 5 June 2014

Wednesday 28 May 2014

Friday 23 May 2014

Tuesday 6 May 2014

Sunday 4 May 2014

Friday 2 May 2014

Subscribe to:

Posts (Atom)